Carbon negative hydrogen production is within reach

There was exciting news this week as a final investment decision was taken by U.S. start-up SGH2 Energy on a waste-to-hydrogen plant in California following sign-off from the city council.

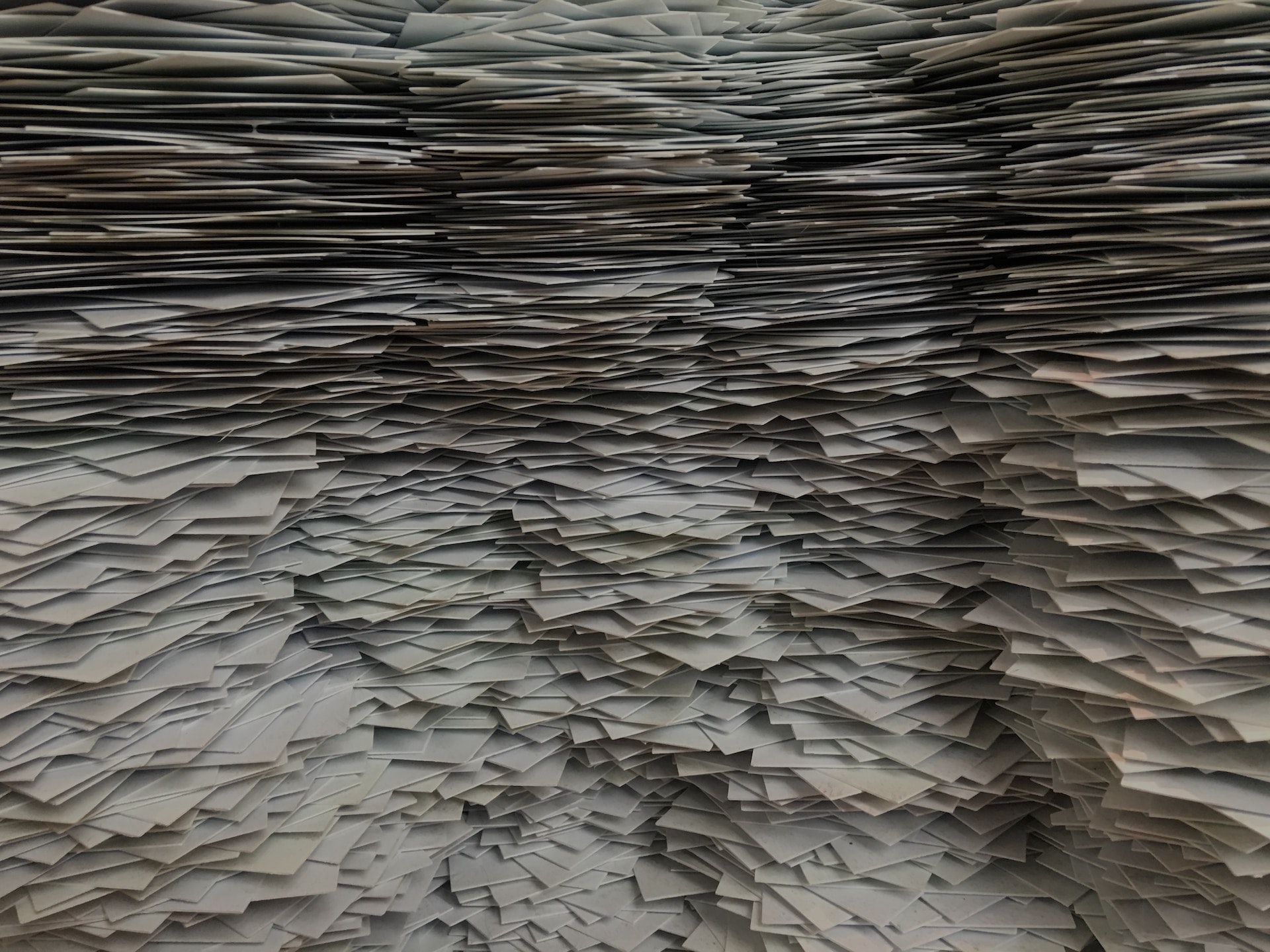

The facility will use its patented plasma-enhanced gasification technology to turn 42,000 tonnes of rejected recycled mixed-paper waste a year into 4,500 tons of “greener than green” hydrogen.

Such projects are carbon negative because the feedstock in the form of waste paper would otherwise have gone to landfill and produced methane, a greenhouse gas 80 times more potent than carbon dioxide.

SGH2’s system uses plasma torches that produce temperatures of up to 4,000 degrees Celsius, turning all solids into gases, about 90% of which is a mixture of hydrogen and carbon monoxide, known as syngas. The carbon monoxide is burned to generate electricity for the process, leaving hydrogen.

While the project represents an important step in the development of carbon negative hydrogen, it is not alone.

U.K. waste-to-hydrogen pioneer Powerhouse Energy has been working with partners to deliver its first facility, at Protos Plastic Park in Cheshire in the northwest of England. Its DMG technology turns a wider range of waste unrecyclable waste, including plastic and end- of-life tyres and turns them into syngas to produce hydrogen, electricity and chemical inputs.

U.K. waste-to-hydrogen pioneer Powerhouse Energy has been working with partners to deliver its first facility, at Protos Plastic Park in Cheshire in the northwest of England.

Luxembourg-based Boson Energy uses a similar process to SGH2. It’s plasma-assisted gasification process turns waste into hydrogen, carbon dioxide and a molten slurry that solidifies into a blue-grey glassy rock.

The UK government has seen the potential in waste-to-hydrogen and provided funding for a number of early-stage projects last year as part of its £5 million Hydrogen BECCS Innovation Programme Phase 1.

Levidian Nanosystems and United Utilities were granted £212,000 for a project to use biogas from wastewater treatment as feedstock to produce hydrogen and graphene through Levidian’s LOOP process.

The UK water industry produces 489 million cubic metres of biogas annually from its anaerobic digestion processes.

Levidian claims its LOOP process produces hydrogen at little to no cost because there is a market for its other product, graphene.

Waste-to-hydrogen technology is also being developed by the University of Aberdeen, which, received £220,000 in funding from the Hydrogen BECCS Innovation Programme.

The University of Aberdeen is working with Cranfield University in England and the University of Verona in Italy to commercialise its four-stage process: dark fermentation, anaerobic digestion, plasma reforming, and steam gasification.

Waste-to-hydrogen technology is also being developed by the University of Aberdeen (pictured Aberdeen, Scotland)

The future of hydrogen is not only green, it’s also a solution to the world’s growing waste problem. And the UK is leading the way by developing cutting-edge technologies that will drive investment in hydrogen for years to come.

To learn more about HYCAP click here.